24-hour hotline:+8613662168047

Keyword search: battery plant , lithium battery factory , power bank works , lifepo4 battery mill , lithium forklift battery manufacturer

What would happen if a lithium battery does not have a protective plate? Generally, batteries have protective plates, and the use of protective plates is also for the safety of batteries. But the function of different types of battery protection boards is also different. I heard that lithium iron phosphate battery packs are not afraid of overcharging or over discharging, so some people think that lithium batteries do not need protective plates. Today, the editor will answer for you.

What is a lithium battery protection board?

Lithium battery protection board, as the name suggests, is used to protect lithium batteries. Lithium battery protection boards are designed to prevent overcharging, over discharging, overcurrent protection, short circuits, and other issues. Some may also install smart chips to record the battery's usage and status.

The lithium battery pack protection board is a charging and discharging protection for series connected lithium battery packs, detecting the overvoltage, undervoltage, overcurrent, short circuit, and overheating status of each individual battery in the battery pack, protecting and extending the battery's service life. When the battery is discharged, the protective plate will protect the battery from over discharging and causing damage to the battery. This adds a protective barrier to lithium batteries, making them safer and extending their lifespan. If there is no protective board, the battery life will not only be affected, but in severe cases, dangerous situations may also occur.

Can lithium battery packs not require protective plates?

The reason why some people have the idea that lithium battery packs do not require protective plates is largely due to the emergence of lithium iron phosphate batteries. Due to reports claiming that lithium iron phosphate battery packs are not afraid of overcharging or over discharging, there has been a debate that lithium batteries can be used without protective plates. However, so far, there have been no battery manufacturers who publicly claim not to use protective boards.

The lithium battery pack protection board is used for charging and discharging protection of series connected lithium battery packs. When fully charged, it can ensure that the voltage difference between individual batteries is less than the set value, achieving uniform charging of each individual battery in the battery pack, effectively improving the charging effect under series charging mode.

When lithium batteries are completely free from the effects of charging, over discharging, etc., and can completely replace the role of protective plates in the design of lithium batteries themselves, lithium batteries can eliminate the need for protective plates. However, at this stage, lithium battery packs still require protective plates. Of course, if the protective board is not designed properly, it can also damage the battery. So, when choosing lithium battery packs, it is best to purchase lithium batteries produced by reputable manufacturers through legitimate channels. In this way, the quality of lithium batteries is more guaranteed.

What would happen if the lithium battery pack does not have a protective board?

If lithium battery packs do not use protective plates, the battery life will be greatly reduced for some electric vehicle users who do not pay attention to daily battery protection, and more fault problems will also occur, leading to some dangerous situations.

During the use of lithium batteries, every overcharge, discharge, or short circuit will reduce the battery life. In severe cases, the battery will be directly scrapped! Generally, the overcharge voltage of a single lithium battery cannot exceed 4.25V, the overcharge voltage cannot exceed 2.75V, and the maximum charge discharge current is 1C (C represents the battery capacity, for example, if the battery is 1200mAh, the 1C charge discharge current is 1.2A). If there is no protective board, directly short circuiting or overcharging the lithium battery pack will cause the battery to bulge, and in severe cases, it may cause liquid leakage, undervoltage, explosion or fire.

The main functions of the lithium battery pack protection board are:

1) Overcharge protection function

The overcharge protection function refers to prohibiting the charger from continuing to charge when a certain voltage (hereinafter referred to as overcharge detection voltage) is reached. That is, the MOS transistor that controls overcharging will enter the off state and stop charging.

2) Overdischarge protection function

The over discharge protection function is to stop discharging the load when the voltage of the battery decreases. Turn off the MOS transistor that controls over discharge and prohibit its discharge. This process is exactly opposite to the action during overcharging detection.

3) Overcurrent protection function

The overcurrent protection function is to stop discharging the load when a large current is consumed. The purpose of this function is to protect the lithium battery pack and MOS tubes, ensuring the safety of the battery in working condition. After overcurrent detection, the battery will return to normal after being disconnected from the load and can be recharged or discharged.

4) Short circuit protection function

Does the lithium battery pack protection board have a balancing function?

It is necessary to have a balanced protection board for lithium battery packs: In the case where the production and storage time of the battery pack is relatively long, due to the different static power consumption of each circuit of the protection board and the different self discharge rates of each cell, the voltage of each series of batteries in the entire battery pack is inconsistent, resulting in a clear voltage difference. However, while ensuring the same capacity, balancing has the function of balancing the voltage of the battery pack, so as to achieve the full charge and full discharge of the battery pack capacity, and maximize the effectiveness of the battery pack.

The situation where balance does not work: Many people believe that lithium battery packs have a balance effect in the middle and later stages of use. In fact, due to the different capacity losses of each battery cell in the middle and later stages of use, a capacity difference cannot be compensated for by the balance of the protection plate. On the surface, the voltage of each string of the battery pack is consistent, but due to the inconsistency of capacity, it is often the low capacity single string battery cells that have over discharge protection and over charge protection first. Therefore, the capacity of the battery pack is reflected in the low capacity single string battery cells. Therefore, we should understand that the protection board is balanced by voltage, and capacity cannot be supplemented.

In summary, the reason why lithium battery packs need protection is determined by their own characteristics. Due to the material of the lithium battery itself, it cannot be overcharged, overdischarged, overcurrent, short circuited, or charged or discharged at ultra-high temperatures. Therefore, a specially designed lithium-ion battery protection plate will always be attached to the lithium battery and its components. It is necessary to use a lithium battery pack protection board, as the circuit of the protection board can separately detect the voltage and current of each battery in the series battery pack, and control the charging and discharging process of the battery pack.

Lithium ForkLift Batteries ,Ensure Quality

Our lithium battery production line has a complete and scientific quality management system

Ensure the product quality of lithium batteries

Years of experience in producing lithium forklift batteries

Focus on the production of lithium batteries

WE PROMISE TO MAKE EVERY LITHIUM BATTERY WELL

We have a comprehensive explanation of lithium batteries

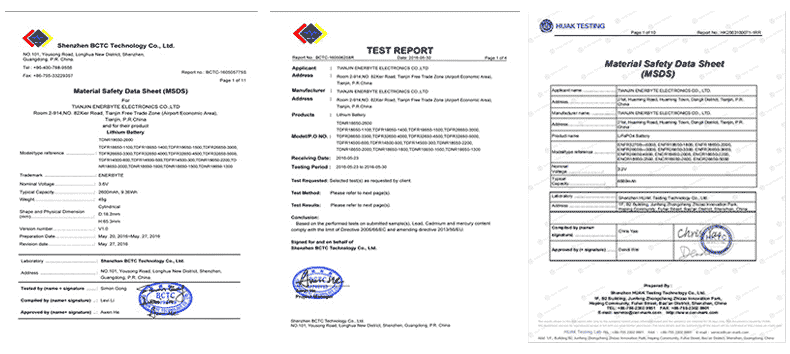

QUALIFICATION CERTIFICATE

THE QUALITY OF COMPLIANCE PROVIDES GUARANTEE FOR CUSTOMERS

MULTIPLE QUALIFICATION CERTIFICATES TO ENSURE STABLE PRODUCT QUALITY

Providing customers with professional and assured products is the guarantee of our continuous progress.

Applicable brands of our products

| Linde Lithium Forklift Battery | Toyota Lithium Forklift Battery | hyster Lithium Forklift Battery |

| jung Lithium Forklift Battery | enrich Lithium Forklift Battery | hyundai Lithium Forklift Battery |

| still Lithium Forklift Battery | heli Lithium Forklift Battery | hangcha Lithium Forklift Battery |

Service hotline

Service hotline