24-hour hotline:+8613662168047

Keyword search: battery plant , lithium battery factory , power bank works , lifepo4 battery mill , lithium forklift battery manufacturer

How to repair a broken lithium battery? Repair method for over discharge of lithium batteries. The common problem with lithium batteries is wear and tear, or in layman's terms, they break down. Generally, lithium battery packs are obtained through many 18650 series parallel connections. What if it breaks down? How to repair lithium batteries? The editor of this article will share his own experience with everyone.

How to repair a broken lithium battery?

If the fully charged voltage is much lower than 4.2V, it indicates that the battery is damaged. If it is a battery that has been used for a long time, it can be determined that the battery has reached its lifespan and its capacity is basically depleted. It should be replaced. There is basically no way to fix it. After all, lithium batteries have a lifespan, not unlimited.

If the battery is measured and there is no voltage, there are two situations. One is that the battery was originally good and stored for a long time due to low power. This type of battery has a certain chance of recovery. Generally, a lithium battery pulse activator is used to charge the battery multiple times in a short period of time. Possible repair. The general repair cost is not low, so it's better to buy a new one

Another possibility is that the battery is completely depleted, the battery separator is broken, and there is a short circuit between the positive and negative electrodes. There is no way to fix this matter. Only new ones can be purchased.

As mentioned earlier, lithium battery packs often become unusable due to one or more damaged batteries. In this case, the voltage at both ends of each battery group should be measured one by one. If there is no voltage or the voltage is significantly low (as described earlier for individual batteries), they should be removed and replaced with new batteries of the same type with similar internal resistance.

After replacement, the lithium battery pack can still be used for a similar lifespan as other batteries. This type of partial replacement generally has a lower cost. It is also a commonly used method in the current market.

Repair methods for lithium batteries in electric vehicles

● Water replenishment

Adding water to a lithium-ion battery in an electric vehicle that has been in use for about 4 months can extend the battery's lifespan, with an average extension time of more than 3 months. It should be noted that after each water replenishment, the battery is in an overcharged state to transition from a "quasi lean liquid" to a "lean liquid" state, and this overcharging is beneficial for improving the battery capacity.

Particle generator

Using a particle generator in parallel on the battery to repair the lithium battery. This method is good for repairing batteries, but due to the thorough repair, if there is no over discharge, it often completely eliminates the possibility of battery vulcanization for continuous use.

● Eliminate vulcanization

Using electric vehicle lithium battery repair equipment, the battery is treated to eliminate vulcanization.

● Reorganize

After the entire set of lithium batteries is damaged, we often conduct charge and discharge testing on the batteries. During the inspection, we often find that 50% of the batteries in a set are not damaged. The reason is that in a series connected battery pack, individual batteries lag behind, resulting in a decrease in the functionality of the entire battery pack, leading to a decrease in the functionality of the entire battery pack.

Comprehensive repair methods

Regular inspection should be carried out on lithium batteries for electric vehicles, with timely sulfur removal and water replenishment. Single batteries should be charged and reassembled. Battery instructions: If it is maintenance free, generally no water needs to be added. If water needs to be added, first check the electrolyte density of the electric vehicle battery itself, and choose the corresponding concentration or no concentration of water to supplement according to different situations, so as to increase the battery capacity or extend its service life.

Repair methods for over discharge of lithium batteries

After the internal storage of lithium batteries is discharged and the voltage reaches a certain value, continuing to discharge will cause over discharge. The discharge cutoff voltage is usually determined based on the discharge current. 0.2C-2C discharge is generally set at 1.0V/cell, while discharge above 3C, such as 5C or 10C, is set at 0.8V/cell. Overdischarge of the battery may cause catastrophic consequences for lithium batteries, especially with high current or repeated discharge, which has a greater impact on the battery.

Generally speaking, over discharge can increase the internal pressure of lithium batteries, disrupt the reversibility of positive and negative active substances, and even if charged, only partially recover, resulting in a significant decrease in capacity.

There are two types of overdischarge in lithium batteries: one is when the voltage of a single cell is zero, and the other is when the voltage of each cell drops outside the detectable range of the charger. Lithium ion battery charging generally adopts a "constant current constant voltage" method, which means that at the beginning, it is charged with standard current for a period of time. When the battery voltage reaches the charging cutoff voltage, constant voltage charging is used. Therefore, it is possible to charge the battery with a DC power source for a period of time, and then switch to the original charger when the cut-off voltage is reached. Although this method is sometimes feasible, it is not always possible, as over discharge of the battery has already affected its performance. However, there are also phenomena where lithium batteries that have been stored for several years can be activated.

How to repair lithium batteries in mobile phones?

1. Gently wipe the metal contacts on the lithium battery and the metal contacts on the phone with a clean eraser or other cleaning tool, which helps with charging conditions and long-lasting power.

2. Wrap the old lithium battery of the phone that will automatically shut down tightly with cling film, and try to wrap it as snugly as possible. There are three layers inside and outside to ensure that the battery is in a vacuum state. Then, wrap three layers of newspaper outside the cling film to completely seal the lithium battery. Put it into the freezer layer of the refrigerator, and after 48 hours, take out the battery and remove the six layers of paper film wrapped around it one by one. The lithium battery did not experience surface expansion or deformation due to freezing. After cooling for a period of time, then charge.

3. Thoroughly discharge the nearly scrapped lithium battery, then recharge and activate the battery. The specific method is to perform deep discharge on the phone, which is to achieve a deeper level of recharging by depleting internal energy, which requires some unconventional methods.

The above are the repair methods for lithium batteries. When using lithium batteries, it is necessary to equip them with protective boards to limit overcharging, over discharging, short circuits, etc., which is beneficial for extending the life of the lithium battery pack. The charging of lithium batteries should not exceed the rated voltage and current, as well as the charging time.

Lithium ForkLift Batteries ,Ensure Quality

Our lithium battery production line has a complete and scientific quality management system

Ensure the product quality of lithium batteries

Years of experience in producing lithium forklift batteries

Focus on the production of lithium batteries

WE PROMISE TO MAKE EVERY LITHIUM BATTERY WELL

We have a comprehensive explanation of lithium batteries

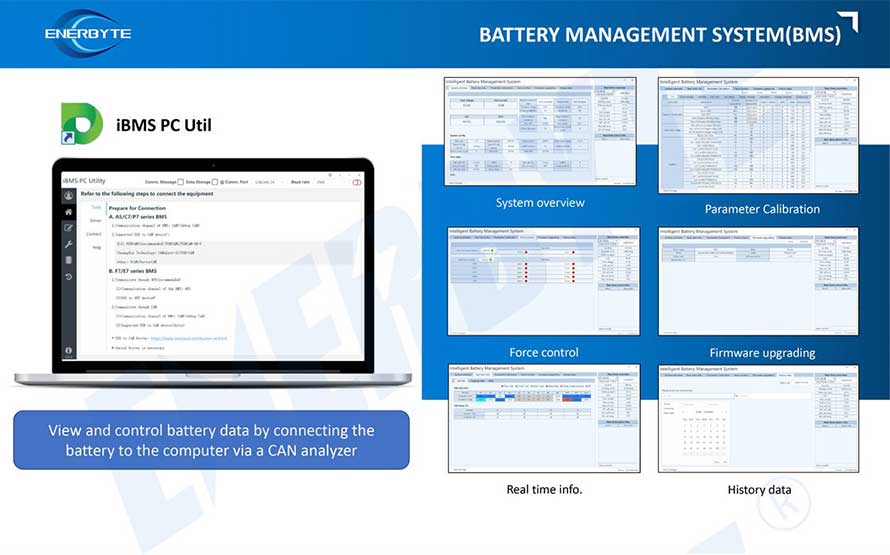

QUALIFICATION CERTIFICATE

THE QUALITY OF COMPLIANCE PROVIDES GUARANTEE FOR CUSTOMERS

MULTIPLE QUALIFICATION CERTIFICATES TO ENSURE STABLE PRODUCT QUALITY

Providing customers with professional and assured products is the guarantee of our continuous progress.

Applicable brands of our products

| Linde Lithium Forklift Battery | Toyota Lithium Forklift Battery | hyster Lithium Forklift Battery |

| jung Lithium Forklift Battery | enrich Lithium Forklift Battery | hyundai Lithium Forklift Battery |

| still Lithium Forklift Battery | heli Lithium Forklift Battery | hangcha Lithium Forklift Battery |

Service hotline

Service hotline