24-hour hotline:+8613662168047

Keyword search: battery plant , lithium battery factory , power bank works , lifepo4 battery mill , lithium forklift battery manufacturer

It does not need to be mixed, with different application fields.

Starting type batteries are used for car starting, with strong instantaneous high current discharge capacity and weak endurance, and belong to the category of liquid rich batteries.

Representative model: 6-QW-60 (550)

6: Number of connected single cells, 12V;

QW: Maintenance free car starting type;

60:20 hour rated capacity, Ah;

550: -18 ℃ starting current, A.

Lead acid power batteries for electric vehicles are used for electric vehicle endurance, with strong deep discharge capacity and weak high current discharge capacity, belonging to the lean liquid type battery.

Representative model: 6-DZM-12

6: Number of connected single cells, 12V;

DZM: Sealed type for electric power assisted vehicles;

12: 2-hour rated capacity, Ah.

Starting batteries are generally rich in type. Power batteries are generally non coupled. The working nature of the starting battery is sudden high current discharge, with large currents ranging from 400-500A, while the power battery is small current discharge, with large currents only 30A. Starting the battery is not difficult, it's just that the discharge current is high and the plates soften a lot.

The main characteristics of starting batteries are thin plates, multiple pieces, which are conducive to high current starting, and a discharge rate of 20 hours. Travel batteries are also power batteries, as they are mainly used for power purposes. The electrode plates are thicker and suitable for current batteries, usually with a discharge rate of 3 or 5 hours. They should all be lead-acid batteries.

1、 Due to different materials, power battery plates are mostly made of lead calcium alloy, while starting batteries are mostly made of lead antimony alloy.

2、 The discharge time is different, and the power battery can discharge at a low current for several hours, with a deep discharge depth. The discharge time of the starting battery is very short,

But running a large discharge current of several hundred amperes.

3、 The electrolyte concentration varies, and in order to run further, many people increase the electrolyte concentration of power batteries to 1.31. In fact, this makes the battery very prone to vulcanization, causing the plates to lose activity. The standard concentration of electrolyte for starting a battery is 1.28, at which a larger discharge current can be obtained, making it easier for the car to start.

1、 Due to different materials, power battery plates are mostly made of lead calcium alloy, while starting batteries are mostly made of lead antimony alloy.

2、 The discharge time is different, and the power battery can discharge at a low current for several hours, with a deep discharge depth. The discharge time of the starting battery is very short,

1、 Different properties

In the case of all new batteries, use a discharge meter to test the battery capacity. Generally, the capacity of power batteries is around 1000-1500mAh; The capacity of ordinary batteries is above 2000mAh, and some can reach 3400mAh.

3、 Different discharge power

A 4200mAh power battery can discharge its energy in just a few minutes, but ordinary batteries cannot do it at all, so the discharge capacity of ordinary batteries is completely incomparable to that of power batteries. The biggest difference between power batteries and regular batteries is their high discharge power and specific energy. Due to the main use of power batteries for vehicle energy supply, they have a higher discharge power compared to regular batteries

4、 Different applications

The battery that provides driving power for electric vehicles is called a power battery, including traditional lead-acid batteries, nickel hydrogen batteries, and emerging lithium-ion power lithium-ion batteries, which are divided into power type power batteries (hybrid vehicles) and energy type power batteries (pure electric vehicles); Lithium batteries used in consumer electronics products such as mobile phones and laptops are generally referred to as lithium batteries to distinguish them from power batteries used in electric vehicles.

The main types of power batteries currently available

At present, the mainstream technologies in the market are still mainly lead-acid battery technology, nickel hydrogen battery technology, fuel cell technology, and lithium battery technology.

lead-acid battery

Lead acid batteries have the longest application history, the most mature technology, and are the cheapest and most affordable batteries, which have achieved mass production. Valve regulated sealed lead-acid batteries (VRLA) were once an important vehicle power battery, applied to many EVs and HEVs developed by European and American automotive companies, such as the Saturn and EVI electric vehicles developed by General Motors in the 1980s and 1990s, respectively.

However, lead-acid batteries have lower specific energy, shorter battery life, higher self discharge rate, and lower cycle life; Its main raw material, lead, has a large weight and may cause environmental pollution from heavy metals during production and recycling. So, currently lead-acid batteries are mainly used for ignition devices during car start-up, as well as small devices such as electric bicycles.

Nickel hydrogen battery

Nickel hydrogen (Ni/MH) batteries have good resistance to overcharging and discharging, without the problem of heavy metal pollution, and there will be no electrolyte increase or decrease during operation, which can achieve sealed design and maintenance free. Compared with lead-acid batteries and nickel cadmium batteries, nickel hydrogen batteries have higher specific energy, specific power, and cycle life.

Its disadvantage is that the memory effect of the battery is poor, and as the charging and discharging cycle progresses, the hydrogen storage alloy gradually loses its catalytic ability, and the internal pressure of the battery will gradually increase, affecting its use. In addition, the expensive price of nickel metal also leads to higher costs.

In terms of key materials, nickel hydrogen batteries are mainly composed of a positive electrode, a negative electrode, a separator, and an electrolyte. The positive electrode is a nickel electrode (Ni (OH) 2); The negative electrode generally uses metal hydride (MH); The electrolyte is mainly liquid, and the main component is potassium hydroxide (KOH). At present, the research focus of nickel hydrogen batteries is mainly on positive and negative electrode materials, and their technological research and development are relatively mature.

Nickel hydrogen batteries for vehicles have been mass-produced and used, making them the most widely used type of in vehicle batteries in the development of hybrid electric vehicles. The most typical representative is the Toyota Prius, which currently has the largest production scale of hybrid vehicles. PEVE, a joint venture between Toyota and Panasonic, is currently the world's largest manufacturer of nickel hydrogen power batteries.

Now that nickel hydrogen batteries have withdrawn from the mainstream power battery lineup, why is Toyota still stubbornly sticking to the nickel hydrogen battery camp?

This has to mention the biggest advantage of nickel hydrogen batteries: super durability!

The famous American automotive media, Consumer Reports, conducted a comparative test on a first generation Prius that had been in use for ten years. The test results show that the first generation Prius model using nickel hydrogen batteries, after driving 330000 kilometers for 10 years, maintains the same level of fuel consumption and power performance compared to the new car, indicating that the hybrid system and nickel hydrogen battery pack are still working normally.

In addition, even after running 330000 kilometers for ten years, this first generation Prius has never had any problems with its nickel hydrogen battery pack, and there has been no questioning from people ten years ago that battery capacity degradation will significantly affect fuel consumption and power performance. From this, it can be seen that the Japanese, who have always been strict and conservative, have a unique reason for their love for nickel hydrogen batteries.

Lithium ForkLift Batteries ,Ensure Quality

Our lithium battery production line has a complete and scientific quality management system

Ensure the product quality of lithium batteries

Years of experience in producing lithium forklift batteries

Focus on the production of lithium batteries

WE PROMISE TO MAKE EVERY LITHIUM BATTERY WELL

We have a comprehensive explanation of lithium batteries

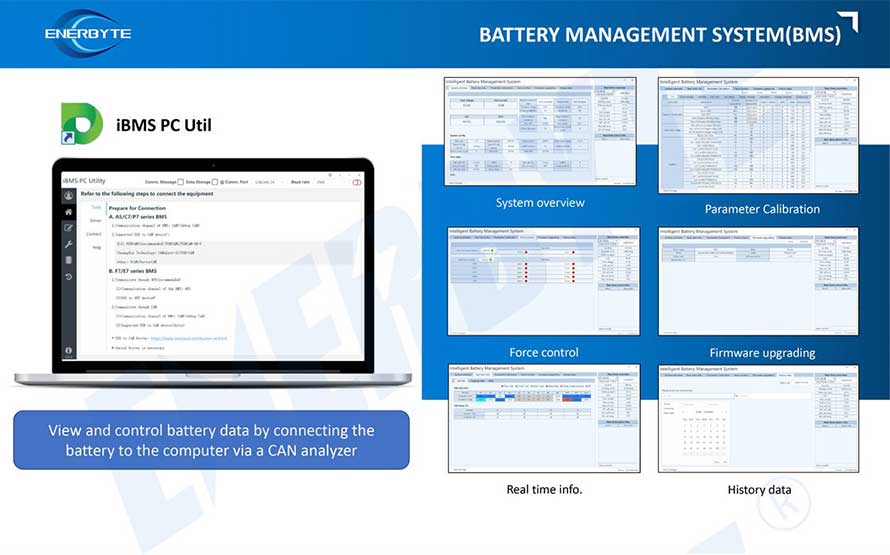

QUALIFICATION CERTIFICATE

THE QUALITY OF COMPLIANCE PROVIDES GUARANTEE FOR CUSTOMERS

MULTIPLE QUALIFICATION CERTIFICATES TO ENSURE STABLE PRODUCT QUALITY

Providing customers with professional and assured products is the guarantee of our continuous progress.

Applicable brands of our products

| Linde Lithium Forklift Battery | Toyota Lithium Forklift Battery | hyster Lithium Forklift Battery |

| jung Lithium Forklift Battery | enrich Lithium Forklift Battery | hyundai Lithium Forklift Battery |

| still Lithium Forklift Battery | heli Lithium Forklift Battery | hangcha Lithium Forklift Battery |

Service hotline

Service hotline